A list of 25 common mono steels in bladesmithing, complete with their alloys, characteristics, quench temperatures, and quench mediums. Clicking on alloys will take you to a page explaining the effects of each alloy on the steel.

If you want any more information on these steels try using “The Smith” chat bot at bottom right of the site. The more specific your question, the more specific his answer should be. For example maybe you want to know more about quenching A2 steel such as plate or interrupted oil quench.

“How to do an interrupted oil quench on A2 steel” should get you a detailed answer.

NOTE: This table only contains references to commercial quench oils. If you are interested in quenching with Mineral Oil or Canola Oil see here: https://blog.smithlist.net/mineral-oil-and-canola-oil-as-knife-steel-quenchants/

| Name | Characteristics | Quench Temperature | Quench Medium | Composition |

|---|---|---|---|---|

| 1095 | High carbon, easy to sharpen, good edge retention | 1475-1525° 802-829C | Oil - Fast quenching such as Parks #50 or Houghton type K. | 0.95% Carbon, 0.4% Manganese, 0.5% Chromium |

| 1080 | Good toughness, easy to heat treat, moderate edge retention | 1450-1500°F 788-816C | Oil - Fast quenching such as Parks #50 or Houghton type K. | 0.80% Carbon, 0.6% Manganese |

| 1075 | Good edge retention, tough, suitable for large blades | 1450-1500°F 788-816C | Oil - Medium such as Parks AAA or Houghton type G. | 0.75% Carbon, 0.7% Manganese |

| 1060 | Good balance of strength and ductility | 1450-1500°F 788-816C | Oil - Medium such as Parks AAA or Houghton type G. | 0.60% Carbon, 0.6% Manganese |

| 1055 | Good toughness, lower edge retention | 1450-1500°F 788-816C | Oil - Medium such as Parks AAA or Houghton type G. | 0.55% Carbon, 0.5% Manganese |

| 1045 | Lower carbon content means less edge retention but increased toughness | 1450-1500°F 788-816C | Oil - Medium such as Parks AAA or Houghton type G. | 0.45% Carbon, 0.6% Manganese |

| 5160 | Excellent toughness and fatigue resistance | 1500-1525°F 816-829C | Oil -Medium to fast such as Parks #50 or Houghton type K or G. | 0.60% Carbon, 0.9% Chromium |

| D2 | High wear resistance and good edge retention | 1850-1950°F 1010-1066C | Air *Cool slowly lime, mica, dry ashes or furnace | 1.5% Carbon, 12% Chromium, 1% Molybdenum |

| A2 | Good toughness and edge stability | 1750-1800°F 954-982C | Air or air + oil depending on cross section size. | % Carbon, 5% Chromium, 1% Molybdenum |

| O1 | Good edge retention and is relatively easy to sharpen | 1450-1500°F 788-816 | Oil - Medium such as Parks AAA or Houghton type G. | 0.9% Carbon, 1.2% Chromium, 0.5% Tungsten |

| S30V | Excellent edge retention and corrosion resistance | 1950-2000°F 1066-1093C | Air | 1.45% Carbon, 14% Chromium, 4% Vanadium |

| VG-10 | Excellent corrosion resistance and edge retention | 1950-2000°F 1066-1093C | Air | 1% Carbon, 15% Chromium, 1% Molybdenum |

| 420HC | Good corrosion resistance but lower edge retention | 1850-1950°F 1010-1066C | Oil - Fast quenching such as Parks #50 or Houghton type K. | 0.46% Carbon, 13% Chromium |

| 440C | High hardness and moderate corrosion resistance | 1850-1950°F 1010-1066C | Oil - Fast quenching such as Parks #50 or Houghton type K. | 0.95-1.20% Carbon, 16-18% Chromium |

| N690 | High corrosion resistance and good edge retention | 1950-2050°F 1066-1121C | Oil - Fast quenching, such as Parks #50 or Houghton type K. | 1.07% Carbon, 17% Chromium, 1.5% Cobalt |

| CPM-154 | Excellent edge retention and corrosion resistance | 1950-2050°F 1066-1121C | Air | 1.05% Carbon, 14% Chromium, 4% Molybdenum |

| Elmax | Very high wear resistance and corrosion resistance | 2050-2150°F 1121-1176C | Air | 1.7% Carbon, 18% Chromium, 1% Molybdenum |

| M390 | Extremely high edge retention and corrosion resistance | 2050-2150°F 1121-1176C | Air | 1.9% Carbon, 20% Chromium, 4% Vanadium |

| H1 | Extremely corrosion-resistant but with moderate edge retention | 1850-1950°F 1010-1066C | Air | 0.15% Carbon, 6.5% Chromium, 0.1% Nitrogen |

| AUS-8 | Good toughness and edge retention | 1850-1950°F 1010-1066C | Oil - Fast quenching, such as Parks #50 or Houghton type K. | 0.75% Carbon, 13-14.5% Chromium |

| Sandvik 12C27 | Well-balanced properties with good hardness and corrosion resistance | 1850-1950°F 1010-1066C | Oil - Fast quenching, such as Parks #50 or Houghton type K. | 0.6% Carbon, 13.5% Chromium |

| 14C28N | Improved edge retention and corrosion resistance | 1850-1950°F 1010-1066C | Oil - Fast quenching, such as Parks #50 or Houghton type K. | 0.62% Carbon, 14% Chromium, 0.2% Nitrogen |

| CTS-XHP | High hardness and edge retention | 1950-2050°F 1066-1121C | Air | 1.6% Carbon, 16% Chromium, 0.45% Manganese |

| 3V | Extremely tough with good wear resistance | 1950-2050°F 1066-1121C | Air | 0.8% Carbon, 7.5% Chromium, 2.75% Vanadium |

| L6 | Known for its toughness and edge retention | 1450-1500°F 788-816C | Oil - Medium such as Parks AAA or Houghton type G. | 0.7% Carbon, 1.25% Chromium, 0.5% Molybdenum |

Edge Quenching – If edge quenching Canola is probably your best bet, as it has the highest flash point.

- Canola: 619F

- Houghton Type K: 334F

- Parks #50: 275F

- Mineral Oil: 275F

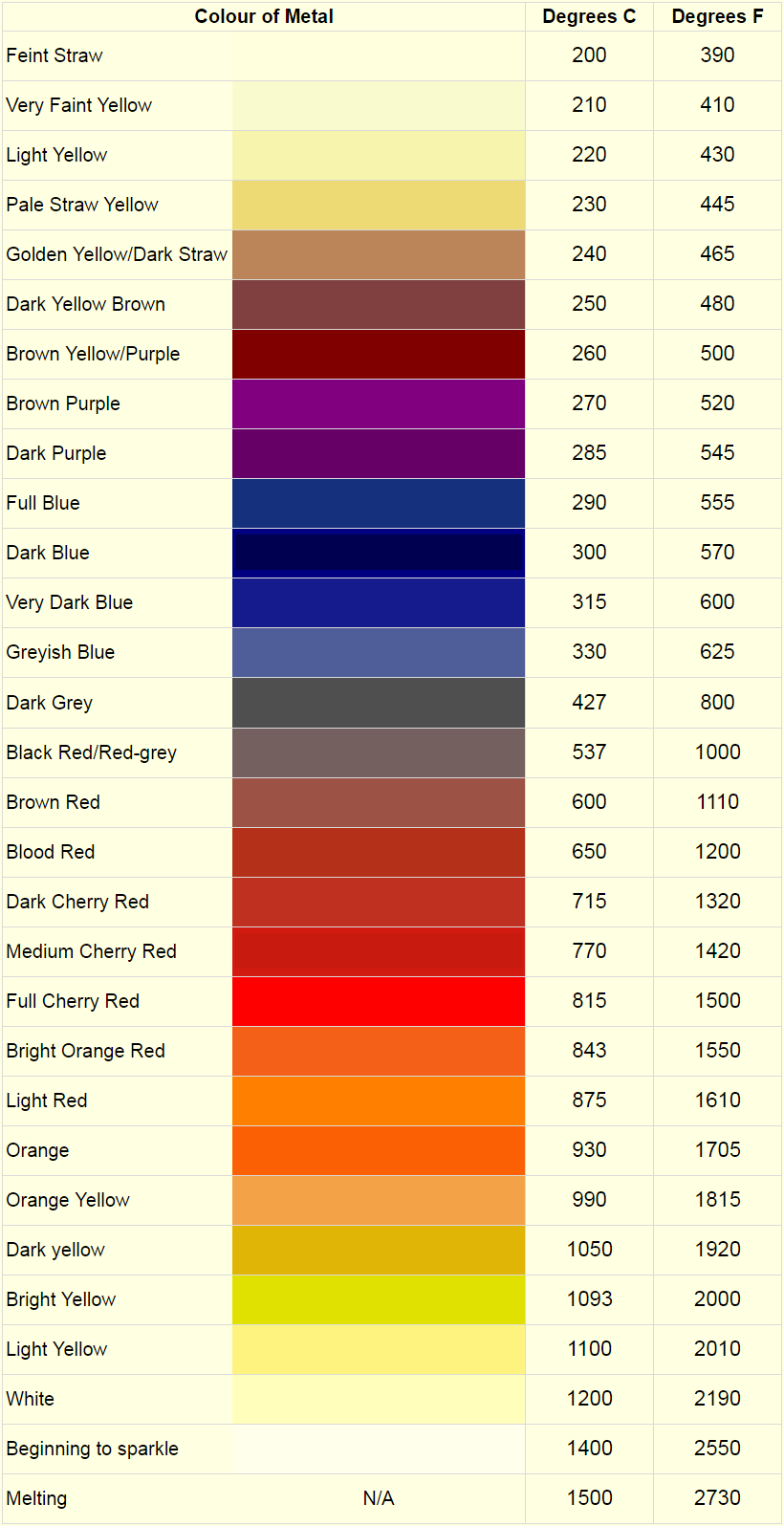

Heated Steel Color Chart